SAINT-BONNET DE MURE, FRANCE - APRIL 15TH, 2016 - Mersen (Euronext FR0000039620 – MRN), a global expert in electrical power and advanced materials, will present at PCIM Europe 2016 its unique solution to get the best of both worlds in power module packaging: high T° (up to 200°C) and low inductance laminated busbar.

Mersen Laminated Busbar, a key enabling technology for high frequency, high voltage and high temperature electronics

SiC and GaN power electronics is now gaining momentum offering a complete range of transistors and diodes with enhanced characteristics compared to incumbent silicon devices:

Higher electron mobility

Higher junction T° (up to 250°C)

Higher switching frequency (several 10’s of kHz)

Higher power density

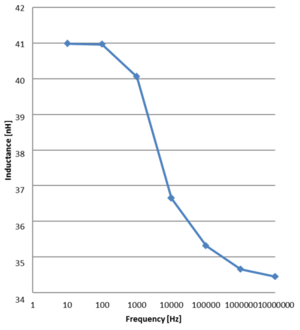

At Mersen, we have increased again our busbar know-how toward carefully selected materials (dielectric and glue), simulation, design rules and related manufacturing process. This enables internal copper busbar compliant with high T° (up to 200°C) and high switching frequency (Stray inductance as low as 35nH in this example).

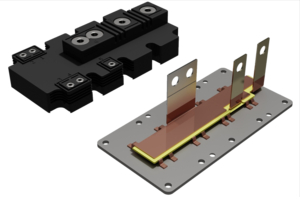

An example of newly designed high T° internal laminated busbar for PrimePack™ power modules

A complete simulation toolset tailored to your power module

Whatever the power module package type, our multiphysics simulation tools will predict mechanical, thermal and electrical behavior of the whole system.

In the following PrimePack™ example, the newly designed laminated busbar simulation has been performed using:

- Distance between the plates : 0.23 mm

- Impedance calculating for the complete loop, without influence of the electronic components

- Material used : copper 1 mm.

- The impedance Z = R + jX has been solved from 10 Hz to 10 MHz.

- The loop inductance L is deduced from the imaginary part of the impedance X using L = X / (2πf)

Simulation of laminated busbar stray inductance in nH as a function of switching frequency