Overview

Mersen proposes a range of On-board resistance. Those resistances have the function to artificially increase the resistance of the connection point in order to “push” the current through the ERCU.

When the train is stopped, the resistance value of the ground brush is superior at the value of the bearing so the current flows through it but when the rotation starts (train in movement speed ≥30 Km/h), the voltage value of the ground brush is inferior to the one of the bearing and the ERCU starts to shunt the current.

This is why you must install a resistance to increase the resistance value in order to keep the current flow through the ERCU even when the train is stopped.

Benefits

Bearing deterioration due to current: Spark erosion

To cross a bearing, the current has to get through the interfaces between the rollers and the rolling surfaces. Then it has to get through the various insulating barriers formed by layers of metal oxides on the surface and by the lubricant.

So the current "breaks through" these dielectric surroundings in a series of small electrical arcs, a phenomenon that is sometimes called sparking.

This causes:

- Brief heating in very limited places of the metal making up the rolling surfaces and the rollers.

- Brief changes in the metallurgical structure, resulting in "crescents of white martensite".

- Those crescents then gradually lose cohesion and flaking develops, increasing over time.

The particles of metal that come loose during this phase will make the rollers slide on their rolling surfaces and impact them in places. This increases the level of vibration and heating in the axle boxes that can eventually lead to seizure and destruction of the bearing.

Bearing deterioration due to current: Loss of lubricant

Current running through a bearing gradually pushes the lubricant out of an axle box.

If two axle boxes are put into a rotation under load and an electric current is run through only one box, there will be a constant oozing of liquefied, blackened grease observed only from the box with the current.

- The exuded oil falls in drops.

- The box's operating temperature rises.

This sweating of grease outside the axle box because of the electric current is due to the phenomenon of electro-osmosis This phenomenon, which can be used to filter a liquid through a partition using an electric current, was discovered by REUSS in 1808 and studied in depth after 1852.

Uses of On-board resistances

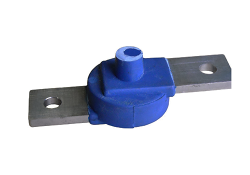

These special resistors are made of conductive ceramics in their mass. They have a high transient energy absorption capacity and are therefore able to withstand very high powers for short periods of time. For the traction market these resistors have the form of discs. They are produced from silico-aluminates and carbon fired at high temperature. This ceramic-type process makes the self-inductance of the material negligible and allows them to withstand the fault currents without damage.

To prevent the resistors to brake due to shock and vibration, Mersen can propose an over-molded version.

Spare part kits

Mersen will supply you all Spare parts kits to guarantee the reliability and the quality time of your equipment system.

- Graphite discs,

- Metal covers,

- Hardware and

- all necessary components

Training and assistance

Mersen Design team is available to support your design and maintenance team’s

Mersen Service team can train your Maintenance team to make the setting and the maintenance of your installations all around the world.

Show less

Capabilities

Product range

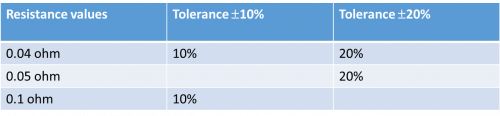

The range proposed by Mersen show 3 resistance values and 2 tolerances values :

Design Guide

Installation

The resistances have to be installed with graphite discs on each side to optimize the electrical contact surface and protected by metal parts.

Tightening torque is Screw mounting with 10Nm torque without grease.

Completed Projects

High speed and Inter city trains

Documents & Resources