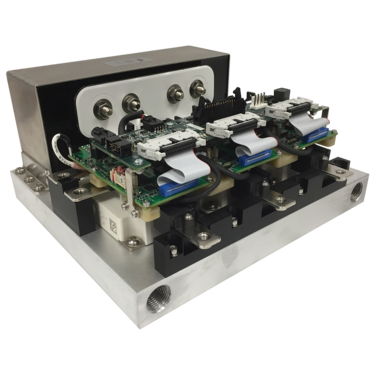

Power Stack Evaluation Kits

Mersen SiC Power Stack Evaluation Kits help inverter designers save time and confusion in selecting individual components and can greatly benefit from a solution that is optimally pre-designed for their specific application.

Benefits

Design control of key customized components down to materials level

Based upon your already existing electrical design and schematics, Mersen teams will jointly discuss the possible design optimization paths, over the 4 key constituent parts of your Inverter/Stack: Cooling, Busbar, Fuse and Capacitors in order to address your most-wanted requirements (efficiency, switching frequency, high T° constraint, size/weight limitation, cost…). This will impact the choice and design of each and every components as well as the selection of the appropriate material (Copper, aluminum, dielectric, polymer…) in a interdependence way.

For other surrounding components (Gate Drivers, Resistors, Magnetics, power modules…) Mersen has already established close collaborations with reputed suppliers who can also be part of the co-design team, beside Mersen engineers.

Accelerated time-to-market

Simultaneously working on several key components design can definitely speed-up the development phase and differentiate yourselves from the competition

System cost optimization / scale effect

This preferential access to 4 main passives (Cooling, busbar , capacitors and fuses) sourced from Mersen will result in an interesting price positioning when the 4 products are ordered from us.

Since we handle rather large cumulative volumes, we are in the position to get better pricings from other component suppliers: modules, connectors, GDU, resistors, inductors…

A total customization approach

No pre-defined technical bricks. We are agnostic towards your choice of circuit topology (3-level, NPC, bi-directional, DC-DC boost / buck, back-to-back…), semiconductor technology (SiC, GaN, Silicon…) and power modules type (single 3-phase, H-bridge, single-leg, single switch…) and package. Customer comes with his design, as it is. We offer a high degree of customization to develop your power stack.

We can study any request for bespoke specifications including customization on dimensions, footprint, geometry, cooling type (air, liquid, heat-pipe…), power range, current rating, switching frequency Fsw, voltage (Modules 1.7kV, 3.3kV or more), AC filtering, etc.

For any kind of customers and business models

- Inverter / Stack design-house with limited or no production capability.

- OEM / stack and inverter manufacturers: specialists and generalists

- System Integrators: Defined converter not their core business

Capabilities

Software simulation of system

Mersen is using complete tool-set of simulation software in order to compute any designs in all physical dimensions: Mechanical, Thermal, Electrical, Electromagnetics. These tools allow us to anticipate the multi-physics interactions between all the components and thus, to select each-other in an optimal mix.

Assembly and testing service

Upon request, for small, medium, or large series, Mersen also offers an assembly service to build YOUR power stack. In addition, Mersen provides both off-load In-Circuit Test (ICT) and on-load test capabilities (Load type: Resistive, Capacitive, or Inductive and testing protocol to be defined with customer).

A global footprint to address any region

Our center of excellence for design, including assembly / test services for low and medium volumes is located in the US. The vast majority of the constituent parts used for stack assembly are designed and manufactured in Mersen facilities all over the globe with dual or triple sourcing capability. Our partners and tier-one suppliers also offer dual sourcing strategy.