Benefits

- Reduction of Temperature of the bus bar and capacitors

- Reduce size of bus bars

- Decrease Semiconductor, input and output T° interconnection

- Increase components lifespan

- Minimize low equivalent resistance

- Minimize low equivalent serial inductance

- Optimize the time and production cost absolutely necessary for EV/ HEV, industrial, solar, wind application, with large volume quantities of laminated bus bar

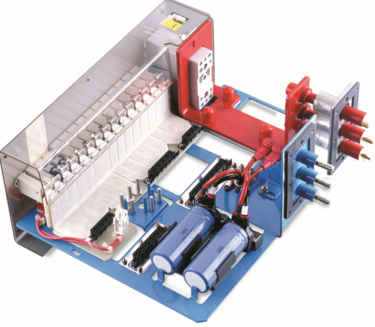

Capabilities

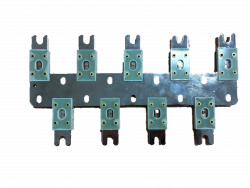

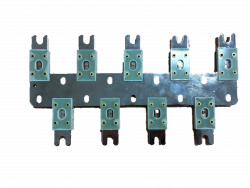

- During bus bar manufacturing process include the components assembly using our brazing and soldering capabilities as well as pressed or screwed technics.

- Integrate fuse function within bus bar.

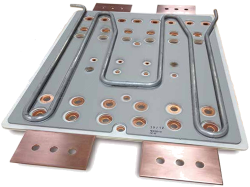

- Leverage our cooling skills to Integrate cooling function into the bus bar and surrounding components.

- Include monitoring sensors in the heart of the assembly where it matters the most.

- Adapt our Capacitors design to optimize integration with Bus Bars.

Design Guide

All that applies to bus bar design is still true for the value Add Bus Bar assemblies but integration of other components will require another level of Consideration to tailor the assembly for the application and maximize performance Including all the components in the design process will allow to optimize weight , volume ,shape , cost while increasing electrical , mechanical and thermal performances .

Thermal Management:

Type of coolant available and what surface need cooling…

Over current Protection:

Electrical characteristics of the circuit and type of protection required need to be defined…

Monitoring:

Define strategic data to collect and what are the sensitive portion of the assembly requiring constant monitoring…

Electromagnetic Shielding:

Consider possible incoming or out going noise pollution emissions from electromagnetic frequencies (EMF) to include proper shielding.

Real estate and final production assembly considerations:

Integration of other components around the bus bar such as printing circuit board, resistors, circuit breakers, cables should be considered to optimize the volume of the assembly and facilitate final assembly process.