Technologies

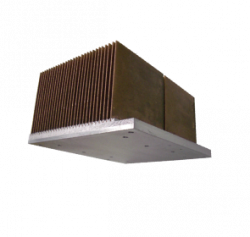

When our all aluminum high performance heat sinks cannot meet the operational performance required and liquid cooling is not an option, it is time to try our mixed metal solution. Weight is a cost driver and a heat sink design that incorporates an aluminum baseplate, copper fins or mixed copper and aluminum fins, provides the highest performance at the lowest cost. The mixed metal heat sink was developed to enhance heat spreading for those semi-conductors developing high heat flux and limited allowable temperature rise. The combination heat sink is offered with MF (3.43 mm) fin spacing and AF (5.49 mm) fin spacing as a standard configurable assembly.

However, we do supply copper baseplates with DF (6.86 mm) spacing using a Hollowfin® which effectively provides MF fin spacing of 3.43 mm with fins up to 118 mm high. No glue is used in the process.

Show less

Benefits

- Enhances heat spreading for high heat flux applications

- Increased performance with use of copper

- Can also apply to dual baseplate

- Aluminum baseplate with Cu or Al/Cu fins

- Copper baseplate and aluminum fins

- Selective use of copper and aluminum fins

- Typically 15 - 25% lower thermal impedance than a glued solution

Applications

- Communications

- Military