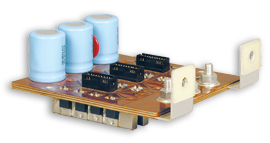

Motor Drive Bus Bar

Thin copper conductors, separated by insulation material of only thousandths of an inch, provides the ultimate in low inductance for IGBT-based motor drives. Incorporating electrolytic capacitors into the same structure simplifies packaging, and reduces the effects of transient overshoots. Note the addition Snubber Capacitors and Resistors built into the laminated bus bar.

Size: 7” x 9” | Thickness: .040” | Voltage: 475VDC | Current: 150A

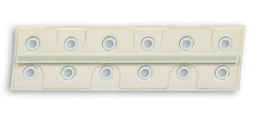

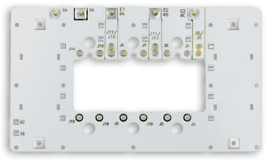

Capacitor Bus Bar for Motor Drive

Six electrolytic capacitors are easily connected to this edge sealed, two-layer laminated bus bar providing a low inductance power path for a low horsepower, variable speed motor drive. Note the use of a bonded insulator strip along the length of the bus bar to provide additional “creepage” protection between the plus and minus terminals.

Size: 1.8” x 6.3” | Thickness: .040” | Voltage: 480VDC | Current: 60A

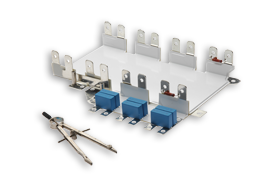

High Current Inverter

A laminated bus bar assembly consisting of three power layers and one signal layer with a total of 59 conductors providing a very low inductance power path and complete gate drive circuitry all designed for a wave-solder assembly process. This bus bar is used in a system powered by 24 MOSFETs, and includes Electrolytic Capacitors, heatsinks and MOVs.

Size: 5” x 7” | Conductors: .060” (gate circuit: .025”) | Volts: 28VDC | Current: 1000A peak

Spacecraft Power Inverter

High current circuit board design using laminated technology for IGBTs and support components. Includes gold plating, quick connect mounting. This laminated bus bar is an enhanced designed of a typical IGBT bus bar. Manufactured to be easily serviced, the design uses gold high current sockets, which are soldered into the DC layers. The design also accommodates resistors and MOVs, soldered right into the assembly. Completely edge filled perimeter, the bus bar also has insulated mounting holes.

Size: 6” x 12” | Thickness: .040” | Voltage: 220V | Current: 75A

Mounting Structure for Capacitor Bank

Laminated bus bars provide a low inductance connection for capacitors. The assembly was designed for an automated production process and the assembly is the DC capacitor bank used in conjunction with high current, high speed switching applications. Positive and negative layers are formed and laminated without outside insulation. This design includes two rows of capacitors soldered into position.

Size: 8” x 8” | Conductors: .030” | Voltage: 63VDC | Current: 300A