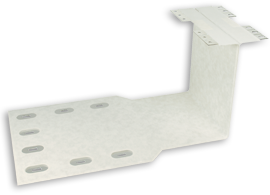

Locomotive

The laminated bus bar shown here represents a single-phase leg for a large three-phase inverter powering modern AC locomotives. Long term durability and continuous operation in hostile environments demand high quality and consistency. The laminated bus bar has mold-sealed edges and fully insulated mounting holes, built and tested to meet customer partial discharge requirements.

Size: 10” x 14” x 30” | Conductors: .030” | Voltage: 1200VDC | Current: 1000A

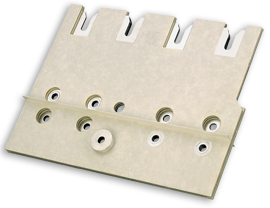

High Speed Traction Drive

Size is never a problem for MERSEN! Modern Traction Inverters are large and so are their components. This three layer, laminated bus bar design delivers low inductance while optimizing the DC capacitor arrangement. Note the use of embossments & soldered bushing “vias” for interconnections.

Size: 10” x 14” x 30” | Conductors: .0340” | Voltage: 1200VDC | Current: 1000A

Locomotive Traction Drive

High horsepower traction drives benefit from the low inductance power path made possible by MERSEN laminated bus bars. Laminated bus bars are the essential component that connect IGBT, SiC or GaN modules and capacitors together. By minimizing system inductance, transient over-shoots are reduced which greatly simplifies the need for complex snubber circuitry. Laminated bus bar designs for motor drives can contain a number of modular bus bars, linked together, to connect all of the system components into one complete system.