High-Frequency Welding

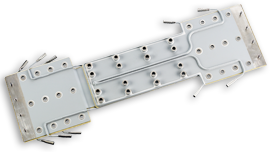

Connecting a complex network including Power IGBTs, Diodes, Resistors, and Film Capacitors, this multi-layer epoxy edge-filled bus bar provides a compact low inductance solution. Thirty-two bushings are brazed into position and maintain tightly controlled coplanar mounting surfaces on both top and bottom. Alternating the plus and minus layers throughout the assembly counters the skin effect of high frequencies.

Size: 5” x 9” | Voltage: 115VDC | Current: 125A | Thickness: .030” & .060”

High Frequency Inverter

High frequency applications present a unique thermal challenge requiring the addition of water-cooling for efficient operation. When thermal considerations exceed conventional means of heat dissipation, one option is to add water-cooling to the system. This design contains five cooling lines soldered directly on to the epoxy powder coated conductors to maintain a constant temperature. Due to the high frequency of the AC voltage, “skin effect” plays a big role in the heat created from the bus and without this additional cooling, the bus would surely overheat.