Why Surge Protection?

What is a surge?

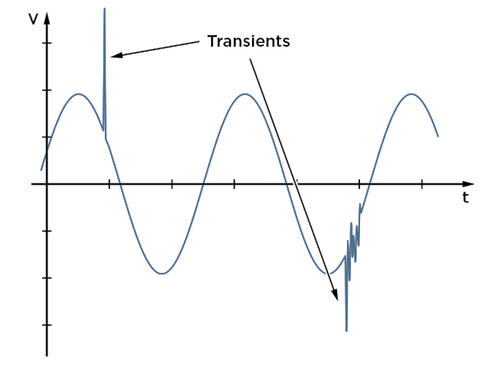

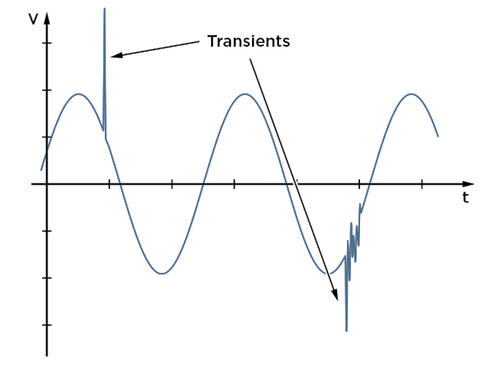

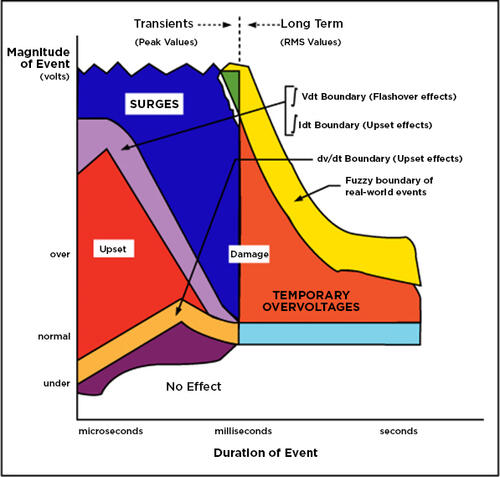

Surge, or transient voltage, is a brief overvoltage spike or disturbance on a power waveform that can damage, degrade, or destroy electronic equipment within any home, commercial building, industrial, or manufacturing facility. Transients or surges can reach amplitudes of tens of thousands of volts, with a duration of less than a half-cycle of the normal voltage waveform.

Every piece of electrical equipment is designed to operate at a specified nominal voltage such as 120 Vac, 240 Vac, 480 Vac, and so on. Most equipment is designed to handle minor variations in their standard nominal operating voltage however, surges can be very damaging to nearly all equipment.

What causes surges?

A common source for surges generated inside a building are devices that switch power on and off. This can be anything from a simple thermostat switch operating a heating element to a switch-mode power supply found on many devices. Surges that originate from outside the facility include those due to lightning and utility grid switching.

Internal sources of surges come from equipment and switching, including:

- Switching of Electrical Loads

- Contactor, relay and breaker operations

- Switching of capacitor banks and loads (such as power factor correction)

- Discharge of inductive devices (motors, transformers, etc.)

- Starting and stopping of loads

- Fault or arc initiation

- Arcing (ground) faults

- Fault clearing or interruption

- Power system recovery (from outage)

- Loose connections

- Magnetic and Inductive coupling

- Elevators, heating ventilation and air conditioning systems (HVAC with variable frequency drives), and fluorescent light ballasts, copy machines, and computers.

External sources of surges

The most recognizable source of surges generated outside the facility is lightning. Although lightning can be somewhat infrequent in certain regions, the damage it can cause to a facility can be catastrophic.

Other external sources of surges include utility-initiated grid and capacitor bank switching. During the operation of the electrical grid, the utility may need to switch the supply of power to another source or temporarily interrupt the flow of power to its customers to aid in clearing a fault from the system. This is often the case in the event of fallen tree limb or small animal causing a fault on the line. These interruptions of power cause surges when the power is disconnected and then reconnected to the customer loads.

Electric utilities produce electricity from a number of power-generation facilities, as utilities switch the supply of power from one grid to another, power disturbances occur, including transients or spikes, and under- and over-voltage conditions.

Why do I need surge protection?

Damages due to electrical surges is one of the leading causes of failure of electrical equipment and it is estimated that damage due to lightning alone costs the US economy $5‐6 billion dollars per year according to the National Lightning Safety Institute. Residences in the US suffered damage to the tune of $825 million according to the Insurance Information Institute in 2016 alone. This number has risen 40% since 2007 due to increase of electronics and electrical equipment susceptible to surge.

The cost of an average downtime for a critical facility due to surge damage is $130,000 per event. On average a typical building experiences surge up to 150 times a month. America’s dependence on connected devices and smart electronics establishes a need to protect the safe and reliable operation of such equipment that is susceptible to electrical surge damage.

Surge protection is a cost-effective solution to prevent downtime, improve system and data reliability, and elimination of equipment damage due to transients and surges for both power and signal lines. It is suitable for any facility or load (1000 volts and below).

How does an SPD work?

A Surge Protective Device - SPD - works like a pressure relief valve in a water system… it is normally installed in parallel with the equipment it’s protecting, connected to ground. Under normal circumstances, at nominal voltage, an SPD will be quietly on guard ready to protect your system. During a surge condition, the SPD becomes a conductor, and drives the potentially damaging transient voltage to ground, protecting your equipment. A properly specified and installed SPD will protect your equipment from many surges over many years- the device is not consumable- once the surge has passed, the SPD will go back to its normal status, not conducting (open circuit to ground) and guarding against future surges.

There are different technologies that can be used for surge protection; Mersen Surge Trap® utilizes Metal Oxide Varistor (MOV) combined with thermal protection for a combination of fast performance and safety.

Show less

Technology and Advantages

Technology

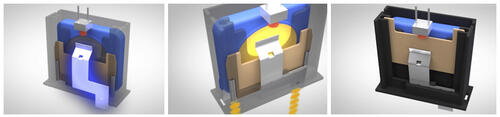

Mersen Surge-Trap® SPDs product line feature our Thermally Protected MOV (TPMOV) technology, a fail-safe, and most reliable surge protection solution on the market.

Mersen’s patented invention TPMOV technology, eliminates common and possibly catastrophically failure when the MOV reaches end of life.

Internally the TPMOV is comprised of a voltage clamping device and a disconnecting apparatus that monitors the status of the metal oxide disk, making the TPMOV a fail-safe device. In the event of an overvoltage breakdown, the metal oxide disc is securely disconnected from the system power by an arc shield.

Upon failure, the TPMOV is also equipped with a visual pin indicator as well as a normally open micro-switch, providing remote indication if applicable.

Mersen TPMOV Technology

TPMOV (Thermally Protected Metal Oxide Varistor) is the backbone of Mersen's extensive surge protection product line. TPMOV eliminates common destructive failure modes associated with standard MOVs.

Advantages

- Thermally Protected MOV (TPMOV) Technology

Using our protection expertise and convinced that technological innovation is essential, Mersen developed the safest surge protection technology. TPMOV eliminates MOV’s hazardous and destructive failure modes (thermal runaway).

- High Short-Circuit Current Rating

Feature high SCCR rating to ensure that Mersen’s TPMOV/SPDs can be installed in almost any location- regardless of available fault current (AFC)- and safely disconnect from the system when necessary.

- Surge Protection Solution for Any Application

We offer different types of mounting option; Panel Mounted – Hard wired, Din Rail SPDs, Surface Mounted, OEM Components, and a big range of voltage configurations ensures the best solution for any application for any application.

- Power distribution systems including service entrance and distribution panels, control cabinets, programmable logic controllers, electronic motor controllers, equipment monitoring, lighting circuits, metering, medical equipment, critical loads, back-up power, UPS, HVAC equipment, data centers, renewable energy such as solar and wind power, among others.

- Industrial automation signaling, cable TV, security systems, alarm signaling, telecommunication and computer networks.

- High Quality

Our products are compliant with the latest ANSI/UL 1449 standards. Mersen’s TPMOV/SPDs are 100% electrically inspected and tested.

- Status Indication & Advanced Options

A wide range of options, including status indicators, remote monitoring and EMI/RFI noise filtering, offers a durable and most reliable surge protection solution.

Show lessApplication Guide

Where do I apply surge protection?

All electrical equipment is vulnerable to electrical surges. Typical SPD applications within industrial, commercial, and residential include:

- Power distribution, control cabinets, programmable logic controllers, electronic motor controllers, equipment monitoring, lighting circuits, metering, medical equipment, critical loads, back-up power, UPS, HVAC equipment

- Communication circuits, telephone or facsimile lines, cable TV feeds, security systems, alarm signaling circuits, entertainment center or stereo equipment, kitchen or household appliances

Location and Amount of Protection

- Categories ("Surge-Trap and the Different kA Ratings" and "UL 1449 4th Edition Location and/or Type Designation")

- System Voltage and Configurations:

- How much protection does my facility need?

Device Types and Performance Parameters

- Voltage protection, clamping voltage, VPR rating- most important/critical to protecting equipment ("Surge Protective Device Performance and Cascaded Protection").

- Inominal Rating

- Imax Rating- Capacity (leads to warranty and life of SPD)

Where do I need to install surge protection?

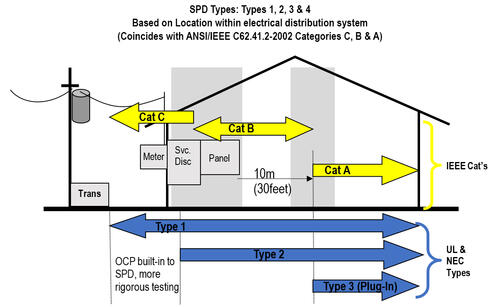

IEEE C62.41.1 defines location categories. These reflect the location in the power system and roughly correspond to UL device types. The Location categories are as follows:

- Location Category C – Outside, service entrance and equipment (Voltage Peak Value 6-10kV)

- Location Category B – Service Equipment, major feeders, and short branch circuits (Voltage Peak Value 3-6kV)

- Location Category A – Long branch circuits and receptacles (Voltage Peak Value 0.5-6kV)

Examples of the locations are as follows:

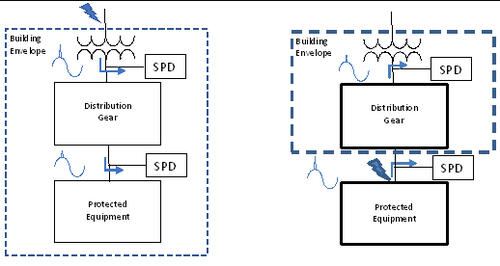

Note that electrical equipment located outside of the building envelope should be considered Category C and Type 1 devices should be utilized at the circuit (more on the device type topic below). The reason is that this equipment is more susceptible to external surge events which can bypass the service SPD and enter the building through the external equipment and wiring. See below for example.

UL Standard 1449 defines several different types of devices based upon their installation location and use. The three most common are described as follows.

- Type 1 – Permanently connected SPDs intended for installation between the secondary of the service transformer and the line side of the service equipment overcurrent device, as well asthe load side, including watt-hour meter socket enclosures and Molded Case SPDs intended tobe installed without an external overcurrent protective device.

- Type 2 – Permanently connected SPDs intended for installation on the load side of the service equipment overcurrent device; including SPDs located at the branch panel and Molded CaseSPDs.

- Type 3 – Point of utilization SPDs, installed at a minimum conductor length of 10 meters (30 feet) from the electrical service panel to the point of utilization, for example cord connected,direct plug-in, receptacle type and SPDs installed at the utilization equipment being protected.See marking in 80.3. The distance (10 meters) is exclusive of conductors provided with or usedto attach SPDs.

System Voltage and Configuration

Knowledge of the system voltage and configuration is critical in determining the correct device for the application. Each device has a maximum continuous operating voltage (MCOV). The MCOV must not be exceed in any of the potential operating conditions of the electrical system, or this could cause unnecessary failure of the device. Given that voltage regulation requirements in the United States allow for up to +/-6 percent of nominal (according to ANSI C84.1), a typical MCOV will be greater than 20 percent above the nominal line-ground voltage. The electrical system configuration is based on the secondary side of upstream transformer, not by how the load is connected. Most SPD mis-orders are misunderstandings related to grounding or neutrals. When a system is referred to as a grounded system, this means that the system is electrically referenced to ground, not that there is a safety ground. By convention, ground wires are not counted as one of the wires for SPDs (3-wire, 4-wire, etc.). Ungrounded and High-Resistance Grounded systems can cause issues with SPDs if they are not properly selected. This is due to the capability of these systems to hold a ground fault indefinitely which can result in raised potential to ground in un-faulted phases. See Mersen Tech Topic TT-SPN4 and Fact Sheet FS-Surge-Electrical-System-Guide for more information.

How Much Protection Does your Facility Requires?

The level of protection your facility requires involves different considerations, which are described in IEEE C62.41.2. When selecting the SPD surge capacity some considerations include:

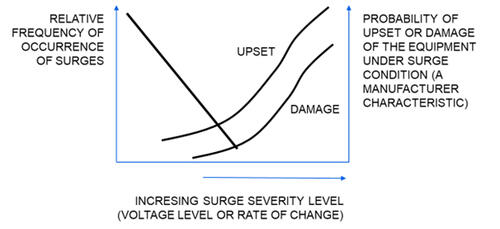

- Protection desired depending upon the application. In applications such as data processing, critical medical processes, or manufacturing processes, any interruption or upset of a process is likely to be unacceptable thus a high protection level would be required.

- Equipment sensitivity to damage from surges. The sensitivities will be different for hardware failure or process upset.

- Value of equipment and downtime: How critical is the load and function of the load?

- Equipment sensitivities

- The power environment – surges

- The power environment – electrical system

- Performance of SPDs

o Protection

o Durability

o Failure mode

- The test environment, proper short-circuit currents

- Total and relative costs

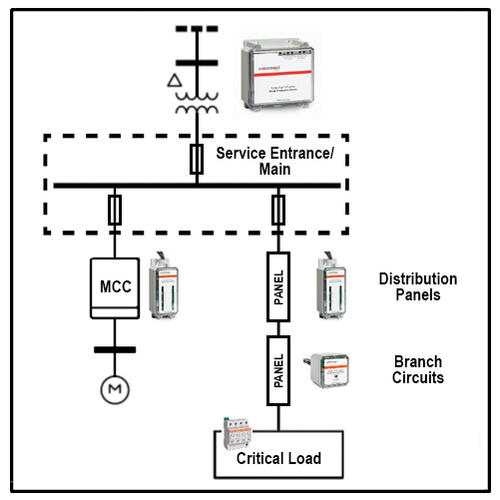

- An electrical system should be fully protected by a system of SPDs, having your highest capacity SPD near the service entrance, and individual panels and pieces of equipment including their own dedicated surge protection as a secondary line of defense.

The equipment susceptibility with the surge environment level involves the probabilistic intersection of two distributions:

Probabilistic concept of surge immunity

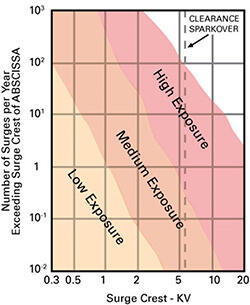

In Low-Voltage (1000 V and Less) AC Power Circuits, IEEE C62.41.2, Recommended Practice on Characterization of Surges describes location categories and exposure levels. Exposure Levels are qualitative:

- Low exposure: applications known for low lightning activity, little load switching

- Medium exposure: systems an d geographical areas known for medium to high lightning activity or with significant switching transients or both

- High exposure: those rare installations that have greater surge exposure than those defined as low or medium

Show less

Codes and Standards

Product Selection and Installation

SPD Selection:

The SPD selection must be done according the to the system network where the sensitive equipment is connected and the level of protection required.

System network considerations that must be taken into account include:

- AC or DC voltage

- Wye or Delta configured circuits

- Nominal System Voltage

- System Grounding

- Product Certifications

Considerations for the level of protection are as follows:

- Maximum Continuous Voltage Rating (MCOV), is the steady state (RMS) voltage that the SPD can withstand without being damaged. A surge is by definition, being a very short term, high magnitude voltage event, that is different from an over-voltage. A damaging overvoltage lasting for even a few cycles (5ms) may be damaging to the SPD. It is important to select an SPD with properly rated MCOV rating, with margin (generally 15-20% is appropriate). (reference EPRI, IEEE)

- Surge Current Capacity, sometimes referred to as Imax takes into account the robustness the SPD and how many surges, that it can withstand / protect the equipment from while in use. Based on a risk analysis of the equipment/location to be protected, the amount of capacity can be increased to help ensure SPD and end use equipment life.

- Nominal Discharge Current Rating (In) Peak value of the current through the SPD (Surge Protection Device), selected by the manufacturer from a list of predetermined values, having a short-circuit current wave shape of 8/20 µs where the SPD remains functional after 15 surges.

- Short Circuit Current Rating (SCCR) based on the available fault current at the location of installation.

- Voltage Protection Rating (VPR): A rating per UL 1449 4th Edition, also referred to as “clamping” voltage, signifies the rounded-up average measured limiting voltage of an SPD (Surge Protection Device) when the SPD is subjected to the surge produced by a 6 kV, 3 kA 8/20 µs combination waveform generator. If all other factors are equal, a lower VPR protects the end use equipment better, but generally, end use equipment is designed to withstand let through voltages of 2kV.

When selecting an SPD it is important to balance all of these factors, the MCOV rating, ensuring sufficient VPR, and ensuring properly surge currents so that the SPD will last. The In value along with the Imax rating is representative of the robustness of the SPD, and its ability to absorb, survive, and mitigate surges over the life of your equipment. SPDs using smaller MOVs will tend to have higher VPR, higher, lower current ratings, and lower life times. Mersen uses high quality, large diameter thermally protected MOVs in its SPDs to be suitable for the most critical loads. See Mersen’s whitepapers on energy absorption of MOVs here and SPD product selection here.

Cascaded Protection Scheme

To maximize system surge protection, system designers and owners often utilize cascaded surge protection. In a cascaded scheme, surge protection devices are utilized in multiple locations throughout the power system. For example, there may be a SPD at the main service entrance, one at each distribution panel or gear, and one at each branch circuit panelboard. Critical equipment may also have SPDs installed on board for additional protection. See Figure below for an example of cascaded protection. Cascading protection has the added benefit of quickly reducing switching surges produced within the facility and preventing them from affecting other equipment.

Installation – Internal vs. External SPD

SPD Lead Length

Since surges are fast transient events, the response of the circuit is different than that of the nominal AC voltage at 50 or 60Hz. The rapid change in voltage appears to the circuit as a high frequency signal and at higher frequencies AC circuits have more impedance. The equivalent frequency of the UL combination wave voltage is 208.3kHz. The main cause of this frequency response is the inductance of the circuit. Simply adding more wire to a circuit adds more inductance and thus higher impedance to the high frequency surge event. Longer lead lengths of SPDs will increase the clamping voltage and reduce their performance in protecting downstream loads. Standard UL VPR testing is performed with 6 inches of lead length. For most applications, this wire lead length is not practical for field installation.

Best Practice in installation is to use the shortest leads possible. Where short leads are not practical, twisting the wire leads will help reduce inductance of the leads and thus reduce the voltage drop and loss of performance. The photo below shows and example of twisted wire leads. See Mersen Tech Topic TT-SPN 8 for more information.

Show less